Что Вы ищете?

Роботизированный шлифовальный станок с ЧПУ

Автоматический шлифовальный станок с ЧПУ

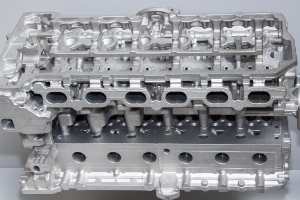

Шлифовальный станок для алюминиевого литья

Интеллектуальный роботизированный шлифовальный станок с ЧПУ

Автоматический шлифовальный станок для алюминия

Автоматический роботизированный шлифовальный станок

Оборудование для шлифования алюминия

Оборудование для постобработки алюминиевого литья